Prof, Dr.-Ing. (Stuttgart), CEng, FIMechE, FIMMM, SFHEA

Reader

- About

-

- Email Address

- amir.siddiq@abdn.ac.uk

- Telephone Number

- +44 (0)1224 272512

- Office Address

Room 271

Fraser Nobel Building

University of Aberdeen

AB24 3UE

Aberdeen

- School/Department

- School of Engineering

Biography

With over two decades of experience, Dr Siddiq is at the intersection of physics-based and AI-driven data simulations in solids and structures. He is a Senior Fellow of Advance HE UK (SFHEA), a Chartered Engineer, and Fellow of IMechE UK (FIMechE) and IOM3 (FIMMM). He is ranked in the list of top 2% world scientists with highest impact in the year 2020-21, & 2022-23 (Stanford University Survey & Elsevier). He has published over 90 articles in world leading international journals and conferences. Some of his articles have been in the list of hottest and most cited articles on Elsevier and ASME lists. He is also a member of advanced manufacturing leadership group as part of Scottish research partnership in engineering. He is also deputy programme lead for UG mechanical engineering, and employability & skills champion for the school of engineering. He has been a university wide committee member which devise the employability framework for the students.

He has a very broad sector experience across higher education institutions, automotive, aerospace, biomedical, oil & gas, and renewable industries. Previously, he has worked at Max-Planck Institute for Metal Research (Germany), Robert BOSCH GmbH (Germany), SKF GmbH (Germany), University of Sheffield (UK), NED University (Pakistan), KAUST (KSA), University of Strathclyde (UK), and Advanced Forming Research Centre (UK). He has extensive international work experience including Germany, UK, Middle East, and South East Asia.

His research grant portfolio in the past is over £2 million. His research is focused on multiscale mechanics of materials, structures and manufacturing processes which include

- hydrogen material interaction

- data driven computational mechanics

- materials through ML and AI

- advanced manufacturing

- integrity assessment

- deformation and failure in materials and their interfaces

- residual stress measurement and predictions

- renewable energy systems

- stress corrosion cracking

My Groups' Research

This video gives you a very high level overview on my research groups activities. Not all the areas are covered. For more details please visit www.amirsiddiq.com

Qualifications

- Dr.-Ing. (PhD) Mechanical Engineering2006 - Max-Planck Institute for Metal Research & University of Stuttgart

- MSc Computational Mechanics of Materials & Structures2003 - University of Stuttgart

- BEng Mechanical Engineering1999 - NED University of Engineering & Technology

- PG Cert Advanced Academic Practice2014 - University of Strathclyde

Memberships and Affiliations

- Internal Memberships

-

- Member of UG teaching and learning committee (UGTLC), University of Aberdeen (UoA), 2020-todate.

- Member of Employability and Entrepreneurship Committee (EEC), UoA, 2021-todate.

- Member of UoA Positive Outcome Taskforce to develop Career Development Framework for Students, 2016 – 2020.

- Undergraduate Deputy Programme Leader (Mechanical Engineering), UoA, 2016-todate.

- Employability Coordinator, School of Engineering, UoA, 2016-todate.

- Deputy Programme Coordinator (MSc Advanced Mechanical Engineering), UoA, 2017-2018.

- External Memberships

-

Professional Affiliations

- CEng, Member, IMECHE – Institute of Mechanical Engineering UK, 2018 – todate

- Felow of Advance HE, 2014- to date

- Member, UKACM – UK Association of Computational Mechanics, 2013-2017

- Member, ASME - The American Society of Mechanical Engineers, 2007-2008

Editorial, Reviewer, Supervision and Examiner

- Book Reviewer: Taylor & Francis Group, CRC Press

- Editorial Board: Journal of Mechanical Engineering and Technology (JMET)

- Proposal Reviewer: Engineering and Physical Sciences Research Council (EPSRC), Leverhulme Trust, Netherlands Organisation of Scientific Research (NWO)

- On the reviewer board of a number of international research journals

- External PhD Examiner (5x Students)

- Member of Advanced Manufacturing Thematic Leadership Group (AM-TLG) as part of National Manufacturing Institute of Scotland (2018-todate)

Committees & Organiser: Conferences, Workshops and Events

- Scientific Committee Member for International Workshop on Computational Mechanics 28 of Materials (IWCMM28), Glasgow, UK, 2018.

- Co-organiser of topical session on Micromechanics of Materials from Atomistic Techniques to Crystal Plasticity Approaches, International Workshop on Computational Mechanics 28 of Materials (IWCMM28), Glasgow, UK, 2018.

- Co-organiser of 1st International Conference on Materials Science and Nanotechnology, Quetta, Pakistan, 2018.

- Technical Programme Committee Member of Conference on Computational Materials Science and Thermodynamic Systems (CMST2018), Cambridge, UK, 2018.

- Organiser of EPSRC sponsored one-day symposium/workshop on Multiscale Mechanics of Deformation and Failure in Materials at University of Aberdeen, 2016.

- Advisory Board Member for International Mechanical Engineering Congress since 2016.

- Scientific Committee Member MMME’14 and MMME’15 (International Conference).

- Co-organiser of Modelling workshop, Advanced Forming Research Centre, UK, 2012.

- Organiser Sheet metal forming workshop, Advanced Forming Research Centre, UK, 2012.

- Co-organiser of mini-symposium on Multiscale constitutive modelling of materials, US National Congress on Computational Mechanics (USNCCM) 11, Minnesota, USA, 2011.

- Organiser of Materials Modelling Colloquium in IMWF, Stuttgart, 2004-2006.

Latest Publications

A study on the potential of cryogenic cooling and cutting technique in reducing the decommissioning cost of offshore monopiles

Cryogenics, vol. 145, 103991Contributions to Journals: ArticlesThe Influence of Post-Thermal Treatments on Microstructure and Mechanical Properties in A20X Alloy Fabricated through Powder Bed Fusion

Journal of Manufacturing Processes, vol. 125, pp. 93-110Contributions to Journals: ArticlesInteraction of defects, martensitic transformation and slip in metastable body centred cubic crystals of Ti-10V-2Fe-3Al: A study via crystal plasticity finite element methods (CPFEM)

International Journal of Damage MechanicsContributions to Journals: ArticlesCrystal plasticity based constitutive model for deformation in metastable β titanium alloys

Modelling and Simulation in Materials Science and Engineering, vol. 32, no. 5, 055023Contributions to Journals: ArticlesStrengthening mechanisms of semi-coherent boundaries between Al8Mn4Y and the Mg matrix in magnesium alloys

Materials Science and Engineering A, vol. 887, 145713Contributions to Journals: Articles

Prizes and Awards

Achievements, Awards and Honours

- World Top 2% Scientist (Stanford & Elsevier Report)

- Fellow Institute of Institute of Materials, Minerals & Mining (FIMMM)

- Senior Fellow Higher Education Academy (SFHEA UK)

- Nominated for Teaching Excellence Award (University of Aberdeen) 2015-16 & 2020-21

- Knowledge Exchange and Commercialisation Award 2020

- Successfully Funded Proposals = 19

- Journal Publications = 38; Conference Papers/Proceedings = 45; Book Chapters = 04

- Internal Research Reports = 09; Invited Talks/Lectures = 13

- Elsevier – Most cited articles published in mechanics of materials (see publications)

- Elsevier – Science-Direct Top25 Hottest Articles (see publications)

- ASME Top10 Hot Article (see publications)

- Session Chair for UKACM 2016 conference held in Cardiff, UK

- Best Teacher Award in Automotive Engineering Department, NED University, 2010

- 2003-2006, Max-Planck Institute Research Fellowship

- Research

-

Research Overview

Amir's research interests fall in the broad category of experimental and computational investigation of materials and manufacturing processes. These include to some extent, the experimental supervision and in great detail the formulating and application of computational frameworks and material constitutive models for metals, soft materials and their interfaces at different length scales. His interests in these models are broad, spanning a wide range of macro-, micro- and nano-scale phenomena. Main areas of his research in the recent past and present include

- deformation and failure in materials and their interfaces (aluminium and alloys, titanium based alloys, niobium, austenitic steels, nickel based superalloys, soft biological materials, shape memory alloys, composites and ceramics)

- machine learning based constitutive modelling of materials

- additive manufacturing (ultrasonic consolidation, 3d metal printing)

- substractive manufacturing (material removal through machining)

- conventional and nonconventional (ultrasonic assisted) forming processes (sheet metal forming, incremental sheet forming, extrusion, wire drawing)

- subsea structural integrity and pipeline design

- residual stress measurement and predictions

- renewable energy systems (wind and wave energy systems)

- stress corrosion cracking

Research Areas

Accepting PhDs

I am currently accepting PhDs in Engineering.

Please get in touch if you would like to discuss your research ideas further.

Research Specialisms

- Mechanical Engineering

- Manufacturing Engineering

- Materials Science

- Solid Mechanics

Our research specialisms are based on the Higher Education Classification of Subjects (HECoS) which is HESA open data, published under the Creative Commons Attribution 4.0 International licence.

Current Research

Amir's research group focusses on a variety of materials and their behaviour along with different types of industrial manufacturing processes. We currently are working on the following projects.

- Machine learning based constitutive modelling of materials

- Additive manufacturing: Metal 3D printing, ultrasonic consolidation

- Effect of microstructure and defect morphology on microstructure based failure of aluminium alloys

- Deformation and failure in single and dual phase titanium alloys

- Multiscale mechanics of stress corrosion cracking

- Metal forming

- Effect of ultrasonic energy on ductile damage of metal

We are always looking for outstanding PhD students, if you are interested in working on any of the above projects then please don't hesitate to contact myself.

Past Research

Selected Research Projects

1. Additive Manufacturing: Metal 3D Printing Using Foils and Powder

a) Laser Assisted 3D Metal Printing

b) Ultrasonic Consolidation [URL]

2. Substractive Manufacturing: Surface Defect Machining [URL]

3. Conventional and Ultrasonic Assisted Forming Processes [URL]

4. Stress Corrosion Cracking [URL]

5. Metal/Ceramic Bicrystal Interface Fracture [URL]

6. Failure Mechanism of Sutured Human Linea Alba Tissue [URL]

7. Ductile Damage due to Void Growth and Coalescence [URL]

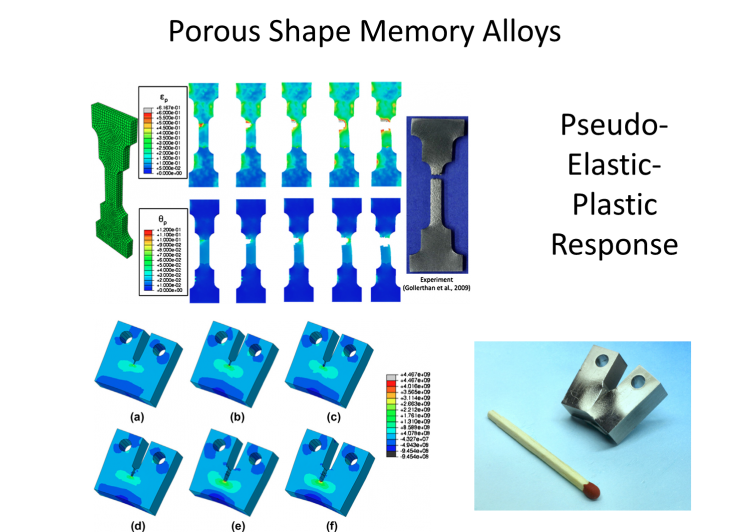

8. Porous Shape Memory Alloys [URL]

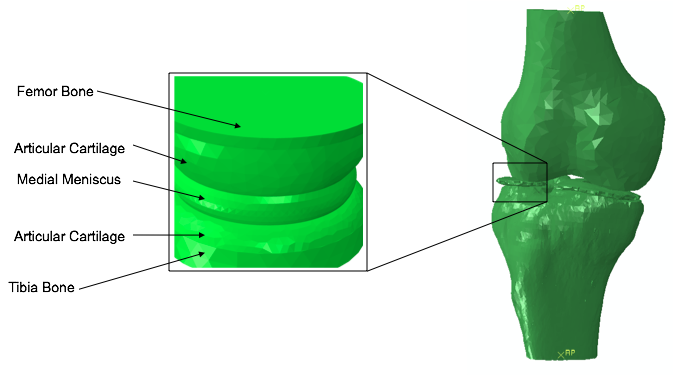

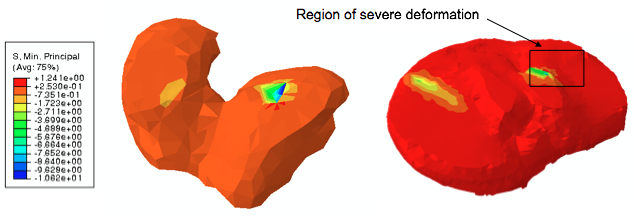

10. Biomechanical Modelling of Knee Joint [URL]

Details about some of the projects can be found on the external link [Please Click Here]

Knowledge Exchange

1. Dynamic Response of a Car Window-Lift Motor Assembly: In collaboration with Dipl.-Ing. Holger Dietzhausen (Robert BOSCH GmbH) and Prof. Kai Willner (Institute A of Mechanics, University of Stuttgart)

2. Diffusion Process (Carburization) Simulation Code: In collaboration with Dr. Juergen Gegner (SKF GmbH) and Prof. Dr.-Ing. Andreas Oechsner (Institute of Applied Mechanics, University of Erlangen)

3. Ultrasonic Consolidation at Macroscale: In collaboration with University of Sheffield, DSTL and Solidica, Inc.

4. Modelling and experiments of two point incremental sheet metal forming process and residual stress measurement and modelling: In collaboration with AFRC, BOEING.

5. Sheet metal forming core research project : In collaboration with AFRC, Rolls Royce plc., BOEING, Barnes Aerospace, and Timet.

6. Residual stress measurement core research project : In collaboration with AFRC, Rolls Royce plc., BOEING, Barnes Aerospace, Timet, and Aubert & Duval.

7. Sheet press forming and incremental sheet forming of titanium alloys: In collaboration with AFRC, Rolls Royce plc., BOEING, Barnes Aerospace, Timet, and Aubert & Duval.

8. Disc project – measurement and prediction of residual stress in quenched components: In collaboration with AFRC, Rolls Royce plc., BOEING, Barnes Aerospace, Timet, and Aubert & Duval.

9. Multi-scale Modelling of Stress Corrosion Cracking by Using Peridynamics: Dr Erkan Oterkus (University of Strathclyde), DSTL UK & Lloyds Register.

10. A Computational Framework for Underwater Shock Response of Marine Structures: Dr Erkan Oterkus (University of Strathclyde), DSTL UK & Lloyds Register.

11. Framework for digitalisation of the fitness for service assessment process: Wilkinson Coutts Engineering UK.

Collaborations

Collaborations and Funding

Supervision

My current supervision areas are: Engineering.

- Ahmad Basem Hany Alsawy (Post doc., 2014-2015)

- Eugene Ogosi (Part Time PhD Student, Primary)

- Umair Bin Asim (PhD Student, Primary, Graduated 2019)

- Kamel Bou Kamel (PhD Student, Second, Graduated 2019)

- Madhava Solanga Arachchige (PhD Student, Second, Graduated 2020)

- Joachim Kölblin (PhD Student, Second)

- Michael Olatunde (PhD Student, Second)

- Peter Christie (PhD Student, Primary)

Funding and Grants

- Longevity and fate of structures left in place, OIL & GAS TECHNOLOGY CENTRE LIMITED, 2020-2024 (£200k) (CI)

- Post decommissioning monitoring, Shell UK,2020-2022 (£ 302.997k) (CI)

- Knowledge Exchange and Commercialisation Award, UoA and WilkinsonCoutts Ltd., 2020 (£ 10k) (PI)

- Induced Ductile to Brittle Transition Impact Cut (IDBTIC), Scottish Funding Council and Clockwise Technologies (Ltd), M. Amir Siddiq (Co-PI), 2019-2023 (£ 122.28k) (CI)

- A Multiscale Constitutive Model for Metals during Sheet Metal Forming Process (EPSRC), 2014-2016 (£98,867.00) (PI)

- A Computational Framework for Underwater Shock Response of Marine Structures (DSTL), M. Amir Siddiq (Co-PI), Period 01-Apr-2014 - 31-Oct-2014 (£27,250.00)

- Multi-scale Modeling of Stress Corrosion Cracking by Using Peridynamics (DSTL), M. Amir Siddiq (Co-PI), Period 01-Apr-2014 - 31-Oct-2014 (£27,255.00 + £15,000.00)

- Disc project - measurement and prediction of residual stress in quenched components (AFRC, BOEING, Rolls Royce, Timet, Aubar & Duvel, Barnes Aerospace), M. Amir Siddiq (Co-PI), Period 01-Jul-2013 - 30-Jun-2014 (£300k )

- Sheet metal forming and incremental sheet forming of titanium alloys (AFRC, BOEING, Rolls Royce, Timet, Aubar & Duvel, Barnes Aerospace), M. Amir Siddiq (Co-PI), Period 01-Jul-2013 - 30-Jun-2014 (£330k )

- EPSRC Small Equipment Grant Scheme for microstructure based modelling of polycrystalline materials (EPSRC), M. Amir Siddiq (PI), Period 01-Nov-2012 (£6.4k)

- Residual Stress Measurement and Predictions (AFRC, BOEING, Rolls Royce, Timet, Aubar & Duvel, Barnes Aerospace), M. Amir Siddiq (Co-PI), Period 01-Aug-2012 - 31-Jul-2013 (£ 175k)

- Sheet Press Forming of Titanium Alloys (AFRC, BOEING, Rolls Royce, Timet, Aubar & Duvel, Barnes Aerospace), M. Amir Siddiq (Co-PI), Period 01-Feb-2012 - 31-Jul-2013 (£ 118k)

- Rate sensitivity effects in nanocrystalline materials during intergranular failure, M. Amir Siddiq (PI), Period 01-Feb-2012 (£5k)

- Incremental Sheet Metal Forming (BOEING), M. Amir Siddiq (Co-PI), Period 01-Feb-2012 - 31-Jul-2013 (£ 125k)

OIL & GAS TECHNOLOGY CENTRE LIMITED - Teaching

-

Programmes

- Undergraduate, 4 year, September start

Deputy Programme Lead

- Undergraduate, 5 year, September start

Deputy Programme Lead

Teaching Responsibilities

- EG5085 (2014-15): ADVANCED TOPICS

Coordinator/Organiser

- EG4578 : GROUP DESIGN PROJECT (BENG Mechanical)

- EG50F8/EG50G8: SUBSEA INTEGRITY

- EG55F2/EG55G2: PIPELINE AND SOIL MECHANICS

- EG59M9: INDIVIDUAL PROJECT IN MSc ADVANCED MECHANICAL ENGINEERING

Supervision Responsibilities

- EG4013 : MEng INDIVIDUAL PROJECTS

- EG4014 : BEng ENGINEERING PROJECTS

- EG5565 : MEng GROUP DESIGN PROJECTS

- EG5908 : MSc INDIVIDUAL PROJECTS (OIL & GAS)

- EG5906/EG5910 : MSc INDIVIDUAL PROJECTS (SAFETY AND RELIABILITY)

- EG59F9/EG59G9 : MSc INDIVIDUAL PROJECTS (SUBSEA ENGINEERING)

- EG59M9: INDIVIDUAL PROJECT IN MSc ADVANCED MECHANICAL ENGINEERING

- EG4578 : GROUP DESIGN PROJECT (BENG)

Courses Taught in the Recent Past:

University of Aberdeen: Advanced Topics, Renewable Energy (Wind), Subsea (Offshore) Integrity, Subsea Pipeline Design, UG/PG individual and group projects.

University of Strathclyde: Advanced Forming Technology and Systems, Advances in Machining, Integrating Studies, Professional Practice, Introduction to Production Engineering, UG/PG individual and group projects.

NED University of Engineering and Technology: FEM: Applications in Automotive Engineering, Finite Element Analysis, Automotive Vechicle Dynamics, Kinematics and Rigid Body Dynamics, Advanced Stress Analysis, Advanced Vehicle Dynamics, UG group projects.

University of Sheffield (as tutor): Engineering Mechanics, Materials under Stress, Thermo-Fluids.

Non-course Teaching Responsibilities

- Programme co-ordinator

- Mentor

- Personal tutor

- Publications

-

Page 1 of 1 Results 1 to 78 of 78

A study on the potential of cryogenic cooling and cutting technique in reducing the decommissioning cost of offshore monopiles

Cryogenics, vol. 145, 103991Contributions to Journals: ArticlesThe Influence of Post-Thermal Treatments on Microstructure and Mechanical Properties in A20X Alloy Fabricated through Powder Bed Fusion

Journal of Manufacturing Processes, vol. 125, pp. 93-110Contributions to Journals: ArticlesInteraction of defects, martensitic transformation and slip in metastable body centred cubic crystals of Ti-10V-2Fe-3Al: A study via crystal plasticity finite element methods (CPFEM)

International Journal of Damage MechanicsContributions to Journals: ArticlesCrystal plasticity based constitutive model for deformation in metastable β titanium alloys

Modelling and Simulation in Materials Science and Engineering, vol. 32, no. 5, 055023Contributions to Journals: ArticlesStrengthening mechanisms of semi-coherent boundaries between Al8Mn4Y and the Mg matrix in magnesium alloys

Materials Science and Engineering A, vol. 887, 145713Contributions to Journals: ArticlesAn investigation on the effect of widespread internal corrosion defects on the collapse pressure of subsea pipelines

Ocean Engineering, vol. 287, no. part 2, 115926Contributions to Journals: ArticlesA Generic Methodology for Predicting the Longevity of Offshore Infrastructure

Chapters in Books, Reports and Conference Proceedings: Conference Proceedings- [ONLINE] DOI: https://doi.org/10.2118/215506-MS

Burst pressure of thin-walled pipes with arbitrarily orientated isolated surface corrosion defect

International Journal of Pressure Vessels and Piping, vol. 203, 104937Contributions to Journals: ArticlesPlastic Softening Induced by High-Frequency Vibrations Accompanying Uniaxial Tension in Aluminum

Nanomaterials, vol. 12, no. 7, 1239Contributions to Journals: ArticlesA Multiscale Constitutive Model for Metal Forming of Dual Phase Titanium Alloys by Incorporating Inherent Deformation and Failure Mechanisms

Modelling and Simulation in Materials Science and Engineering, vol. 30, no. 2, 025008Contributions to Journals: ArticlesDeformation of AlSi10Mg parts manufactured by Laser Powder Bed Fusion: In-situ measurements incorporating X-ray micro computed tomography and a micro testing stage

Procedia Structural Integrity, vol. 35, pp. 168-172Contributions to Journals: ArticlesEffect of Hydrogen and Defects on Deformation and Failure of Austenitic Stainless Steel

Recent Developments in Analytical Techniques for Corrosion Research. Toor, I. U. (ed.). Springer International Publishing AG, pp. 235-257, 23 pagesChapters in Books, Reports and Conference Proceedings: Chapters- [ONLINE] DOI: https://doi.org/10.1007/978-3-030-89101-5_11

- [ONLINE] View publication in Scopus

Mesoscale Model for Predicting Hydrogen Damage in Face Centred Cubic Crystals

Physical mesomechanics, vol. 24, pp. 588-597Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1134/S1029959921050106

Data Driven Finite Element Method: Theory and Applications

Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, vol. 235, no. 17, pp. 3329-3339Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1177/0954406220938805

- [OPEN ACCESS] http://aura.abdn.ac.uk/bitstream/2164/16657/1/Siddiq_JMES_DataDrivenFinite_AAM.pdf

- [ONLINE] View publication in Scopus

A new route for developing ultrafine-grained Al alloy strips using repetitive bending under tension

Materials & Design, vol. 206, 109750Contributions to Journals: ArticlesComputational Modelling of Microstructural Deformation in Metastable β Titanium Alloys

UK Association of Computational Mechanics ConferenceContributions to Conferences: AbstractsCrystal Plasticity based Study to Understand the Interaction of Hydrogen, Defects and Loading in Austenitic Stainless Steel Single Crystals

International Journal of Hydrogen Energy, vol. 45, no. 56, pp. 32632-32647Contributions to Journals: ArticlesMechanical response and microstructure evolution of commercially pure titanium subjected to Repetitive Bending under Tension

Materials & Design, vol. 193, 108814Contributions to Journals: ArticlesHydrogen effect on plastic deformation and fracture in austenitic stainless steel

Contributions to Journals: Conference Articles- [ONLINE] View publication in Scopus

Deformation and failure in nanomaterials via a data driven modelling approach

Theoretical and Applied Mechanics Letters, vol. 10, no. 4, pp. 249-252Contributions to Journals: Articles- [ONLINE] https://arxiv.org/abs/1910.00966

- [ONLINE] DOI: https://doi.org/10.1016/j.taml.2020.01.029

- [OPEN ACCESS] http://aura.abdn.ac.uk/bitstream/2164/14851/1/Siddiq_TAML_Deformation_VOR.pdf

- [ONLINE] View publication in Scopus

Modelling Hydrogen Induced Stress Corrosion Cracking in Austenitic Stainless Steel

Journal of Mechanics, vol. 36, no. 2, pp. 213-222Contributions to Journals: ArticlesFormability of AA-7075 Sheets Subjected to Repetitive Bending Under Tension

Contributions to Conferences: PapersA CPFEM based study to understand the void growth in high strength dual-phase Titanium alloy (Ti-10V-2Fe-3Al)

International Journal of Plasticity, vol. 122, pp. 188-211Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.ijplas.2019.07.002

- [OPEN ACCESS] http://aura.abdn.ac.uk/bitstream/2164/14653/1/Umair_Manuscript_2019_rev3.pdf

- [ONLINE] View publication in Mendeley

- [ONLINE] View publication in Scopus

Representative volume element (RVE) based crystal plasticity study of void growth on phase boundary in titanium alloys

Computational Materials Science, vol. 161, pp. 346-350Contributions to Journals: ArticlesA porous crystal plasticity constitutive model for ductile deformation and failure in porous single crystals

International Journal of Damage Mechanics, vol. 28, no. 2, pp. 233-248Contributions to Journals: ArticlesHydrogen effect on fracture behaviour of austenitic stainless steel

Contributions to Conferences: PapersDesign and validation of a fixture for positive incremental sheet forming

The Journal of Engineering Manufacture, vol. 232, no. 4, pp. 629-643Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1177/0954405417703423

Hydrogen effect on plastic deformation and void growth in austenitic stainless steel

Contributions to Conferences: PapersRVE based crystal plasticity study of void growth on phase boundary in titanium alloys

Contributions to Conferences: PapersThree-dimensional in situ observations of compressive damage mechanisms in syntactic foam using X-ray microcomputed tomography

Journal of Materials Science, vol. 52, no. 17, pp. 10186-10197Contributions to Journals: ArticlesVoid growth in high strength aluminium alloy single crystals: a CPFEM based study

Modelling and Simulation in Materials Science and Engineering, vol. 25, no. 3, 035010Contributions to Journals: ArticlesSmooth particle hydrodynamics study of surface defect machining for diamond turning of silicon

The International Journal of Advanced Manufacturing Technology , vol. 88, no. 9-12, pp. 2461–2476Contributions to Journals: ArticlesA Thermomechanical Approach of Modeling Martensitic Transformation Using Crystal Plasticity Theory

International Conference on Martensitic TransformationsContributions to Conferences: AbstractsRepresentative Volume Element (RVE) based crystal plasticity study of void growth at phase boundary in titanium alloys

7th National Student Conference in Metallic MaterialsContributions to Conferences: PostersPeridynamic modeling of composite laminates under explosive loading

Composite Structures, vol. 144, pp. 14-23Contributions to Journals: ArticlesModelling of Stress-Corrosion Cracking by Using Peridynamics

International Journal of Hydrogen Energy, vol. 41, no. 15, pp. 6593-6609Contributions to Journals: ArticlesA Crystal Plasticity Finite Element Method (CPFEM) based study to investigate the effect of microvoids in single crystalline aluminium alloy

Chapters in Books, Reports and Conference Proceedings: Conference Proceedings- [ONLINE] DOI: https://doi.org/10.13140/RG.2.1.2866.5208

Crystal Plasticity based Finite Element Analysis of Void Growth in High Strength Alloys

Contributions to Conferences: PapersNiobium/alumina bicrystal interface fracture

Multiscale Materials Modeling: Approaches to Full Multiscaling. Schmauder, S., Schäfer, I. (eds.). Walter de Gruyter, pp. 135–150, 16 pagesChapters in Books, Reports and Conference Proceedings: Chapters- [ONLINE] DOI: https://doi.org/10.1515/9783110412451-009

Void Growth in Aluminium Alloys – A CPFEM based study

Contributions to Conferences: PapersA multiscale phenomenological constitutive model for strain rate dependent tensile ductility in nanocrystalline metals

Materials Letters, vol. 142, pp. 60-63Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.matlet.2014.11.112

- [OPEN ACCESS] http://aura.abdn.ac.uk/bitstream/2164/4231/1/NC_RateSENS_Paper.pdf

- [ONLINE] View publication in Scopus

A numerical investigation on the effect of tool geometry in single point diamond turning of silicon

Chapters in Books, Reports and Conference Proceedings: Conference ProceedingsExperimental Study of Incremental Sheet Forming Process using CPTi

Chapters in Books, Reports and Conference Proceedings: Conference Proceedings- [ONLINE] DOI: https://doi.org/10.1002/9781119296126.ch239

Incremental Sheet Forming Fixture Design and Implementation

Contributions to Conferences: PapersMultiphysics modelling of Stress Corrosion Cracking by using peridynamics

Analysis and Design of Marine Structures V. Guedes Soares, C., Shenoi, R. A. (eds.). CRC Press, pp. 499-504, 6 pagesChapters in Books, Reports and Conference Proceedings: Chapters (Peer-Reviewed)Multiscale deformation and failure in aluminium alloy 6082-T6: Experiments and Modelling

Contributions to Conferences: PapersNumerical simulation of triaxial tests to determine the Drucker-Prager parameters of silicon

Chapters in Books, Reports and Conference Proceedings: Conference Proceedings- [ONLINE] DOI: https://doi.org/10.1109/IConAC.2015.7313993

Improvement in ductility in commercially pure titanium alloys by stress relaxation at room temperature

Chapters in Books, Reports and Conference Proceedings: Conference Proceedings- [ONLINE] DOI: https://doi.org/10.4028/www.scientific.net/KEM.611-612.92

- [ONLINE] View publication in Scopus

Complex Incremental Sheet Forming Using Back Die Support on Aluminium 2024, 5083 and 7075 alloys

Procedia Engineering, vol. 81, pp. 2298-2304Contributions to Journals: ArticlesA phenomenological variational multiscale constitutive model for intergranular failure in nanocrystalline materials

Materials Letters, vol. 107, pp. 56-59Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.matlet.2013.05.097

- [ONLINE] View publication in Scopus

A multiscale constitutive model for intergranular stress corrosion cracking in type 304 austenitic stainless steel

Journal of Physics: Conference Series, vol. 451, no. 1, 012022Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1088/1742-6596/451/1/012022

- [OPEN ACCESS] http://aura.abdn.ac.uk/bitstream/2164/5903/1/jpconf13_451_012022.pdf

- [ONLINE] View publication in Scopus

Ultrasonic consolidation: multiscale models and numerical simulations

Contributions to Conferences: PapersA phenomenological two-phase constitutive model for porous shape memory alloys

Computational Materials Science, vol. 60, pp. 44-52Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.commatsci.2012.02.031

- [ONLINE] View publication in Scopus

Ultrasonic-assisted manufacturing processes: variational model and numerical simulations

Ultrasonics, vol. 52, no. 4, pp. 521-529Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.ultras.2011.11.004

- [ONLINE] View publication in Scopus

A variational void coalescence model for ductile metals

Computational Particle Mechanics, vol. 49, no. 2, pp. 185-195Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1007/s00466-011-0639-9

- [ONLINE] View publication in Scopus

A thermomechanical crystal plasticity constitutive model for ultrasonic consolidation

Computational Materials Science, vol. 51, no. 1, pp. 241-251Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.commatsci.2011.07.023

- [ONLINE] View publication in Scopus

Finite element analysis of ultrasonic insertion of SiC fibre in aluminium alloy 6061

International Journal of Materials Engineering Innovation, vol. 2, no. 3-4, pp. 182-202Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1504/IJMATEI.2011.042876

- [ONLINE] View publication in Scopus

Simulation of peel test of ultrasonic consolidated metal structures using cohesive model

Contributions to Conferences: PapersA microscale thermomechanical constitutive model for ultrasonic consolidation processes

Contributions to Conferences: PapersFibre embedding in aluminium alloy 3003 using ultrasonic consolidation process-thermo-mechanical analyses

The International Journal of Advanced Manufacturing Technology , vol. 54, no. 9-12, pp. 997-1009Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1007/s00170-010-3007-6

- [ONLINE] View publication in Scopus

Acoustic softening in metals during ultrasonic assisted deformation via CP-FEM

Materials Letters, vol. 65, no. 2, pp. 356-359Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.matlet.2010.10.031

- [ONLINE] View publication in Scopus

Modeling of acoustic softening effects in metals using crystal plasticity theor: a micromechanics based model

Contributions to Conferences: PapersMultiscale simulation of metal/ceramic interface fracture

IUTAM Symposium on Multi-Functional Material Structures and Systems. Dattaguru, B., Gopalakrishnan, S., Aatre, V. K. (eds.). Springer, pp. 343-355, 13 pagesChapters in Books, Reports and Conference Proceedings: Chapters (Peer-Reviewed)- [ONLINE] DOI: https://doi.org/10.1007/978-90-481-3771-8_35

Fiber push-out study of a copper matrix composite with an engineered interface: Experiments and cohesive element simulation

International Journal of Solids and Structures, vol. 46, no. 25-26, pp. 4277-4286Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.ijsolstr.2009.08.021

- [ONLINE] View publication in Scopus

Theoretical and FE analysis of ultrasonic welding of aluminum alloy 3003

Journal of Manufacturing Science and Engineering, Transactions of the ASME, vol. 131, no. 4, pp. 0410071-04100711Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1115/1.3160583

- [ONLINE] View publication in Scopus

Microstructural analysis of ultrasonic welded AA6061 by electron backscattered diffraction

Rare Metal Materials and Engineering, vol. 38, pp. 147-151Contributions to Journals: ArticlesUltrasonic welding in implanting reinforcing fibre in aluminum matrices

Contributions to Conferences: PapersModelling and characterization of ultrasonic consolidation process of Aluminium alloys

Chapters in Books, Reports and Conference Proceedings: Conference Proceedings- [ONLINE] View publication in Scopus

Thermomechanical analyses of ultrasonic welding process using thermal and acoustic softening effects

Mechanics of Composite Materials, vol. 40, no. 12, pp. 982-1000Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.mechmat.2008.06.004

- [ONLINE] View publication in Scopus

Ultrasonic consolidation of passive/active fibres in aluminium alloy: a finite element approach

Contributions to Conferences: PapersNiobium/alumina bicrystal interface fracture: a theoretical interlink between local adhesion capacity and macroscopic fracture energies

Engineering Fracture Mechanics, vol. 75, no. 8, pp. 2320-2332Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.engfracmech.2007.09.005

- [ONLINE] View publication in Scopus

Multiscale modelling of interface fracture

Contributions to Conferences: PapersSimulation of ultrasonic welding of fibre elements in metal matrices

Contributions to Conferences: PapersUltrasonic consolidation as a novel manufacturing technique in embedding passive/active fibres in metal matrices

Contributions to Conferences: PapersModelling of crystal plasticity effects on the crack initiation energies of a bi-crystal interface (Nb/Al2O3)

Computer Assisted Mechanics and Engineering Sciences, vol. 14, no. 1, pp. 67-78Contributions to Journals: Articles- [ONLINE] View publication in Scopus

Fracture of bicrystal metal/ceramic interfaces: A study via the mechanism-based strain gradient crystal plasticity theory

International Journal of Plasticity, vol. 23, no. 4, pp. 665-689Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1016/j.ijplas.2006.08.007

- [ONLINE] View publication in Scopus

Interface fracture analyses of a bicrystal niobium/alumina specimen using a cohesive modelling approach

Modelling and Simulation in Materials Science and Engineering, vol. 14, no. 6, pp. 1015-1030Contributions to Journals: Articles- [ONLINE] DOI: https://doi.org/10.1088/0965-0393/14/6/009

- [ONLINE] View publication in Scopus

Simulation of hardening in high purity niobium single crystals during deformation.

Steel Grips: Journal of Steel and Related Materials, vol. 3, no. 4, pp. 281-286Contributions to Journals: Articles