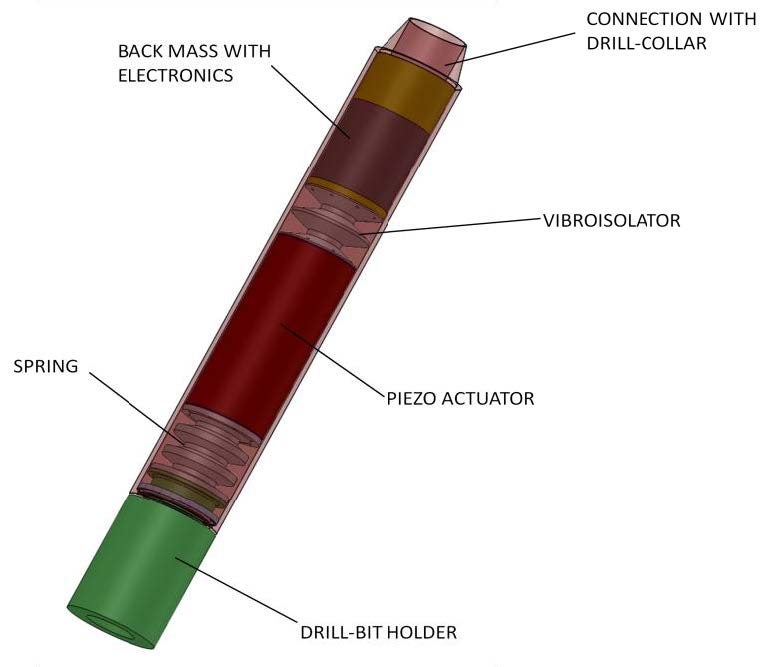

The technology comprises a relatively compact module with an integral resonator and high frequency actuator (exciter) which is located in the drill string just above the bit (oscillating mass). The actuator, which will be powered by a downhole turbine, utilises an array of piezo-electric or magneto-restrictive electrically controlled displacement transducers excited at a frequency that develops resonance conditions in the drilling zone. A vibration isolation unit effectively decouples the resonator from the drill string allowing all the drilling energy to be focused at the bit.

The controllable dynamic loading can be tuned in real time downhole for drill rate optimisation of the formations being drilled. At- or near- resonance conditions in the drilling zone between the drill bit and formation are maintained for varying drilling environments by adjusting the frequency and amplitude of the excitation to develop resonance in the drilled formation producing a steady propagating localised fracture zone immediately ahead of the bit.

The test rig drilling trials to date have achieved excellent results using commercially available drill bits, but it is anticipated that a parallel project to optimise bit design, by reducing mass and modifying cutting structure, will offer further improvement.

The technology is compatible with existing downhole drilling and measurement tools and can be run in on- or off- mode. The on-mode provides the additional controllable enhancement while the off-mode allows unaffected conventional rotary drilling. When run in the on-mode the weight-on-bit requirements are greatly reduced resulting in significantly lower torque and drill string vibration, and the periodic contact action of the bit results in less friction at the drilling interface. It is in relation to this more benign operating environment that wider drilling efficiencies are achieved.

Benefits

The non-linear resonances which result in a controllable dynamic stress field and focused impact energy at the bit increases drilling efficiency compared to the predominantly shearing and crushing action of conventional rotary drilling and RED has the potential to offer the following operational and economic benefits;

-

Faster instantaneous drilling rates - increased rate of penetration results from focusing drilling energy at the bit and the forward migrating stress crack front

-

Reduced non-productive time and extended bit life - reduced: weight-on-bit, torque, drill string vibration and friction at the bit results in reduced: wear on downhole equipment and incidences of drill string failure, and longer bit runs reduce the necessity to trip

-

Better well bore quality - unique mode of operation, focused energy and reduced drilling time produces a smoother profile more stable well bore

-

Reduced time on well/location - faster drill rates and reduced non-productive time from reduced trips and incidence of tool or drill string failure, create substantial time savings on rig costs/daily operation costs

-

Potential to access energy resources thought inaccessible or uneconomic at current technology capability - particularly where substantial sections of hard rock drilling are encountered

-

Smaller environmental footprint - less time on site therefore less fuel/energy usage and lower emissions across the whole operation

-

Health & Safety gains - from reduced operational exposure time, reduced tripping time and improved worker occupational health environment

-

Opportunity to commercialise in a number of industry sectors - the novel intellectual property embedded in RED has potential applications across a wide range of drilling situations including hand tools, construction, mining, geothermal and water